Wye Delta Starter Troubleshooting

Wye/delta is used in high voltage transmission, and wye/wye is seldom used because of potential unbalance. There is always transition spike when motor from star go to delta connection.this spike can be a reason for your problem and breaker tripping.sometime installation of the timer and 0,5 sec.

When the start command is issued, contactor 1m is closed, connecting the motor in a wye configuration.

Wye delta starter troubleshooting. So what you have in your case is a 75kw generator out of sync with the supply that is now reconnected to the supply at some completely random phase angle. Once the motor runs at full speed in wye, disconnect the power to the wye contactor coil, let the speed fall to half, and then connect power to the coil of the delta contactor. This way, star delta starter can be only used for light load during starting the motor.

(known as wye/delta starters in the 60hz world). This would require another timer. As its an unloaded start id set the wye delta to a second before the unloaders kick in.

It is very important that while connected in star, the motor is allowed to accelerate to full speed before switching to delta. This method is actually reduced voltage but is accomplished by changing the motor phase connections such that a winding that is designed to run with phase voltage equal to line voltage on delta connection is wye connected for starting to put less than line voltage on each phase. So let’s take it one by one:

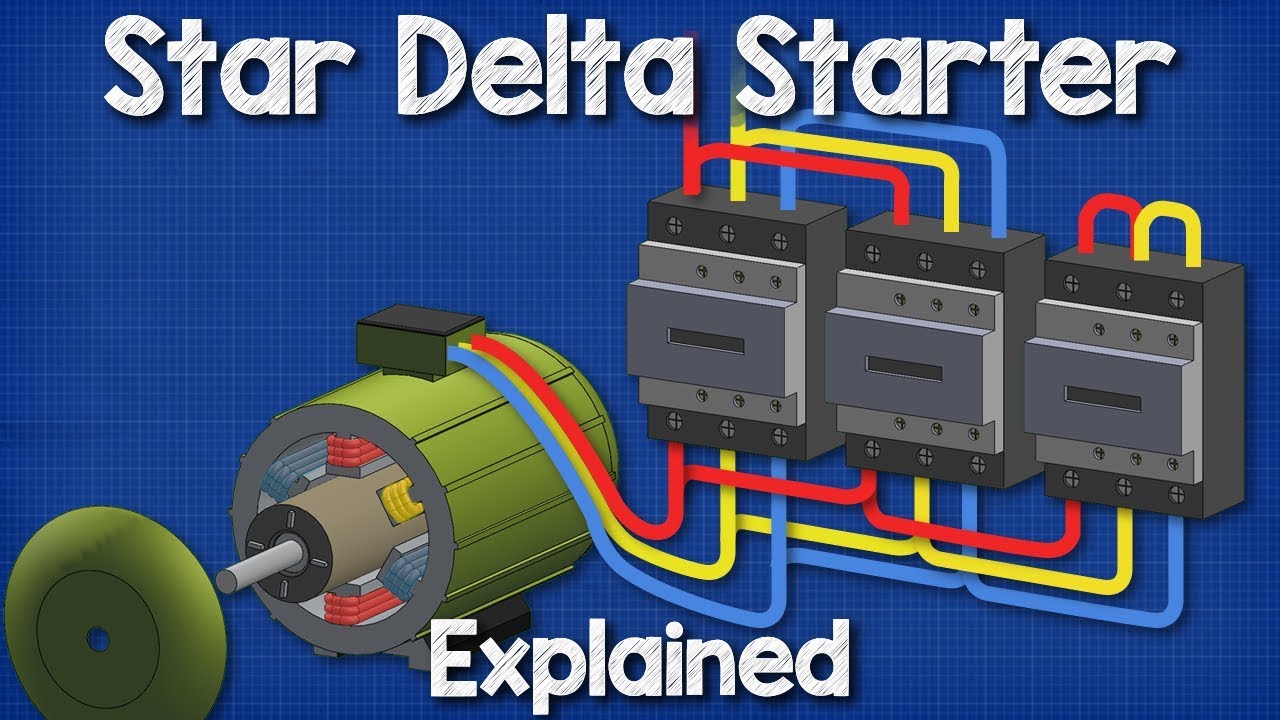

The star/delta starter is manufactured from three contactors, a timer and a thermal overload. If you switch to delta at less than 90% speed, you will have a very high start current until the motor reaches full speed. 1) the motor in delta will draw full voltage start current for the speed that it is rotating.

Specify forms only if any of the coils are at. You switch from wye to delta after 2.5 to 4 seconds, but the switch is instantaneous. This is a great way.

Figure 3 is the schematic for a delta/wye configuration. See specifications for the necessary codes and instructions for ordering. Closed transition starters do not permit this peak to occur.

Before troubleshooting the 3 phase induction motor, we must have to know about the 3 phase induction motor, star delta starter and it’s connection diagram. In many, if not most, cases the star/delta starter does little to reduce problems, infact it commonly exacerbates them. Www.pdhcenter.com pdhonline course e413 www.pdhonline.org.

While keep in mind that star delta starter can only be used for low to medium voltage and light starting torque induction motors. 3 phase induction motor have 3 winding; Both the line and control voltage must be specified to order this product.

Every winding has its own resistance. The percent voltage applied during the start in the wye is 58% of full voltage, resulting in a percent of full load starting torque of 33%. The contactors are smaller than the single contactor used in a direct on line starter as they are controlling winding.

A method of reduced voltage starting that first connects a motor in a wye to reduce voltage, then reconnects the motor in a delta to provide full line voltage. Time without voltage on motor terminal before delta connection is good remedy for that problem. Wye without transition to delta.

Even on an unloaded start a 300hp will need more than 2 seconds to get away. Alarm 9973 or 4.9973 invalid power control state detected when the machine accelerates to maximum rpm. Use the clamp you have.

They are used in an attempt to reduce the start current applied to the motor during start as a means of reducing the disturbances and interference on the electrical supply. A type of reduced voltage starter that makes use of the characteristics of wye and delta connections to reduce voltage without lowering current. The initial connection should be in the star pattern that results in a.

Wye delta contactor how it works and troubleshooting guide customer resource center diagram in pictures database exam motor control wiring just download or read control wiring gina crawford putco tailgate wiring onyxum com The wye/delta patch is enabled and the wye/delta contactors do not have a feeback cable. The counter emf should have been reduced.

Both types are diagrammed in accompanying illustrations. The primary is wound as delta, and the secondary is wound as wye. The star/delta (or wye/delta) starter is one of the lowest cost electromechanical reduced voltage starters that can be applied.

You can get 2x short circuit currents. Delta/delta is used in many industrial installations, while delta/wye is the most common configuration. Assume u, v and w.

Here we are giving you only overview on 3 phases induction motor. Three phase dol starter control overload indicator power wiring diagram. No factory modifications (forms) are available with the oem.

Star delta starter power circuit wiring diagram.

0 Response to "Wye Delta Starter Troubleshooting"

Post a Comment